Stepper motors play a critical role in modern technology, powering everything from precision machinery to 3D printers and robotics. Their ability to deliver accurate control and repeatable motion makes them a preferred choice in applications requiring fine positioning. However, the true potential of a stepper motor can only be unlocked with a well-matched stepper motor driver, which acts as the bridge between the motor and its control system.

In this article, we will delve into the essential aspects of stepper motor drivers, exploring their function and significance. We’ll then examine related topics such as stepper motor current management, the integration of stepper motor drivers with Modbus communication, and the role of USB stepper motor controllers in modern designs. Whether you are an engineer, a hobbyist, or a technology enthusiast, this guide will help you understand the components and considerations involved in optimizing stepper motor performance for various applications.

Understanding the Role of a Stepper Motor Driver

Stepper motors are known for their ability to execute precise movements, but this precision is only achievable when paired with the right stepper motor driver. A stepper motor driver serves as the intermediary between the motor and its control system, translating digital signals into the electrical pulses that drive the motor. These devices are crucial for regulating speed, direction, and positioning, enabling the motor to perform with accuracy and efficiency.

Key Functions of a Stepper Motor Driver

At its core, a stepper motor driver has three primary functions: current regulation, pulse generation, and motor protection. The driver ensures that the stepper motor receives pulses in a sequence that corresponds to the desired motion, allowing for precise step-by-step rotation. Moreover, stepper motor drivers help control the current supplied to the motor, ensuring that it operates within safe limits to prevent overheating or damage.

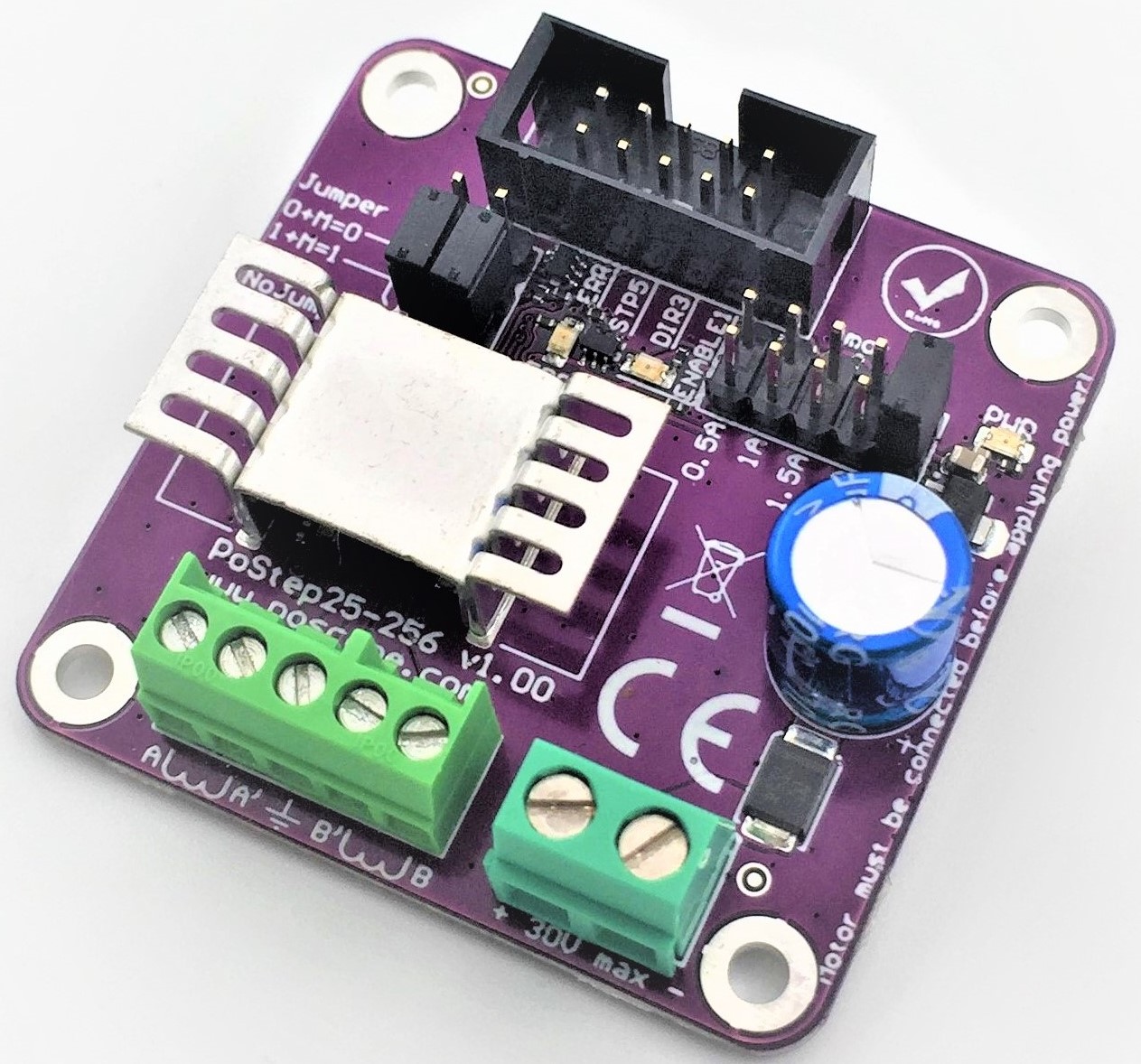

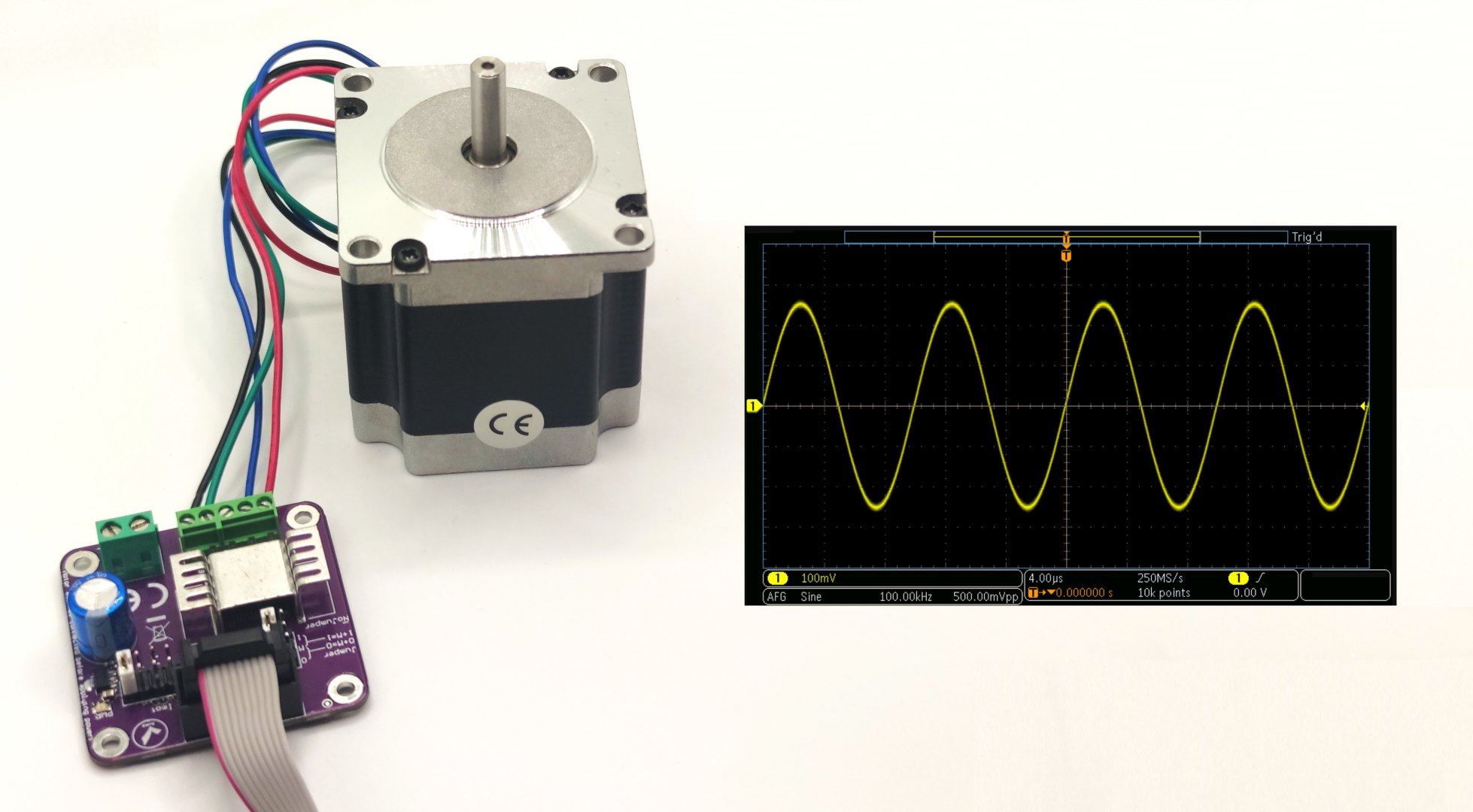

Modern stepper motor drivers often come equipped with advanced features such as microstepping. Microstepping divides each full step of the motor into smaller steps, improving smoothness and resolution. This feature is particularly valuable in applications requiring ultra-fine positioning, such as CNC machines and medical devices.

Types of Stepper Motor Drivers

There are various types of stepper motor drivers available, each tailored to different applications. Common categories include:

Unipolar Drivers: These drivers are simpler in design and control current in one direction through each coil. While easy to use, they are less efficient than bipolar drivers.

Bipolar Drivers: These drivers allow current to flow in both directions through the coils, providing greater torque and efficiency.

Integrated Drivers: These combine the driver and motor into a single unit, simplifying installation and reducing the footprint of the system.

Choosing the right type of stepper motor driver depends on factors such as the motor type, application requirements, and desired level of control.

Importance of Compatibility

The compatibility between the stepper motor and its driver is a critical consideration. Factors like voltage, current ratings, and control signals must align to achieve optimal performance. Mismatched components can result in poor performance or even permanent damage to the motor or driver. Engineers and designers must carefully analyze datasheets and specifications to ensure compatibility.

Why Stepper Motor Drivers Are Indispensable

Without a stepper motor driver, achieving the precision and repeatability that stepper motors are renowned for would be nearly impossible. These devices empower users to harness the full capabilities of stepper motors, making them indispensable in industries ranging from manufacturing to robotics. In essence, the stepper motor driver is the brain behind the motor’s movement, providing the intelligence needed for accurate control.

This foundational understanding of stepper motor drivers sets the stage for exploring related topics, such as managing stepper motor current and leveraging advanced communication interfaces like Modbus and USB for more sophisticated applications.

Managing Stepper Motor Current for Optimal Performance

The performance and longevity of a stepper motor depend heavily on how its current is managed. Stepper motor current refers to the flow of electrical energy through the motor’s coils, which generates the magnetic fields needed to drive its movement. Proper current control is essential to achieving accurate motion, minimizing heat buildup, and preventing damage to both the motor and its driver.

Why Stepper Motor Current Matters

Current is the driving force behind a stepper motor’s torque. Higher currents generally result in greater torque, which is beneficial for demanding applications. However, excessive current can lead to overheating, increased wear on components, and inefficiencies. Conversely, insufficient current may result in a loss of torque and precision, causing the motor to underperform.

A stepper motor driver plays a pivotal role in managing the current supplied to the motor. By maintaining the current within safe limits, the driver ensures that the motor operates efficiently without compromising its reliability.

Techniques for Current Control

Modern stepper motor drivers employ several techniques to regulate current, including:

Chopper Control: This widely used method adjusts the voltage supplied to the motor coils, ensuring that the current remains constant even as the motor’s resistance changes. It helps maintain torque while minimizing heat.

Current Limiting: Drivers are typically equipped with a configurable setting to cap the maximum current delivered to the motor. This feature is crucial for protecting the motor from excessive current draw.

Dynamic Current Adjustment: Advanced drivers can dynamically adjust the current based on the motor’s load and speed, enhancing efficiency and reducing power consumption.

Impacts of Improper Current Management

Failing to manage stepper motor current properly can have several adverse effects, including:

- Overheating: Excessive current causes the motor to overheat, potentially leading to insulation failure and permanent damage.

- Reduced Efficiency: Inefficient current control wastes energy, resulting in higher operating costs and reduced system performance.

- Noise and Vibration: Unstable current can produce unwanted noise and vibration, particularly in high-precision applications.

- Shortened Lifespan: Over time, poor current management can accelerate wear and tear on both the motor and its driver.

Optimizing Current for Specific Applications

Different applications demand varying levels of current control. For instance:

- High-Torque Applications: Industrial machinery may require higher currents to achieve the necessary torque for heavy loads.

- Precision Applications: Devices like 3D printers or medical imaging equipment benefit from finely tuned current settings to ensure smooth and accurate motion.

- Energy-Efficient Designs: In portable or battery-powered devices, minimizing current is essential for extending battery life without sacrificing performance.

Advanced Features for Current Management

Many modern stepper motor drivers offer advanced features to simplify current management. For example, some drivers allow for automatic current reduction when the motor is idle, reducing heat and conserving energy. Others provide real-time monitoring capabilities, enabling users to track current usage and make adjustments on the fly.

Properly managing stepper motor current is key to unlocking the motor’s full potential while ensuring long-term reliability and efficiency. As we’ll explore in the next chapter, integrating stepper motor drivers with communication protocols like Modbus adds another layer of control, enabling more sophisticated and versatile applications.

Stepper Motor Driver with Modbus: Enhancing Communication and Control

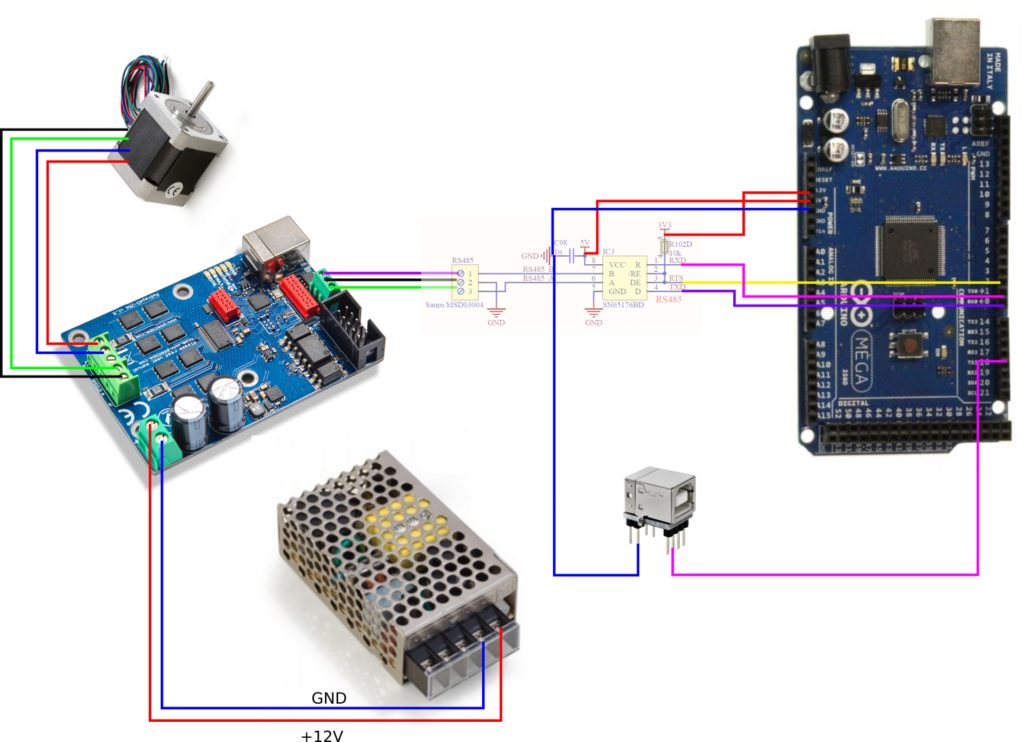

In many industrial and automation applications, stepper motor drivers must work seamlessly with larger control systems. Modbus, a widely used communication protocol in industrial environments, provides a solution for integrating stepper motor drivers into complex systems. By utilizing Modbus, engineers can remotely monitor and control stepper motors, enhancing the flexibility, efficiency, and scalability of their designs.

What is Modbus?

Modbus is an open communication protocol that allows for the transmission of data between devices over a serial line or network. It is simple, reliable, and widely adopted in automation systems, making it ideal for communication between a stepper motor driver and other system components, such as programmable logic controllers (PLCs), sensors, or human-machine interfaces (HMIs). Modbus can operate over both RS-232 and RS-485 communication standards, offering flexibility in terms of system architecture.

How Modbus Works with Stepper Motor Drivers

When a stepper motor driver incorporates Modbus communication, it can receive control signals, transmit motor status information, and even adjust operating parameters in real-time. This integration allows for remote configuration, monitoring, and troubleshooting, which are crucial in large or complex systems.

A typical stepper motor driver with Modbus support can perform a variety of functions via Modbus commands, including:

Speed Control: Adjusting the motor’s speed dynamically based on input from the control system.

Positioning Feedback: Sending information back to the control system regarding the motor’s current position, allowing for precise control.

Current Monitoring: Reporting real-time current usage and other diagnostic data to ensure that the motor operates within safe limits.

Motor Protection: Implementing safety protocols by shutting down or adjusting the motor’s operation when certain thresholds are exceeded, such as overcurrent or overtemperature conditions.

This level of communication is especially beneficial in applications like factory automation, robotics, and CNC machinery, where precise control over many motors is required from a central control unit.

Benefits of Using Modbus with Stepper Motor Drivers

Integrating Modbus into stepper motor driver systems offers several advantages:

Remote Control and Monitoring: Modbus allows operators to manage stepper motors from a distance, reducing the need for manual adjustments and increasing system uptime.

Improved Diagnostics: With real-time data feedback, users can detect issues early and perform preventive maintenance, minimizing downtime and avoiding expensive repairs.

Simplified System Integration: Modbus provides a standardized communication protocol, making it easier to integrate stepper motors into diverse automation systems without the need for custom solutions.

Scalability: Modbus can connect multiple devices on the same network, enabling the management of large-scale systems with multiple stepper motors without requiring a separate controller for each unit.

Practical Applications of Stepper Motor Drivers with Modbus

The combination of stepper motor drivers with Modbus communication is widely used in a range of industries, including:

- Manufacturing: In automated production lines, stepper motors with Modbus-enabled drivers control conveyor belts, assembly robots, and other machinery, ensuring precise synchronization.

- Robotics: Modbus allows for efficient communication between stepper motor drivers and a robot’s central controller, enabling coordinated movement for complex tasks.

- CNC Machines: Stepper motors with Modbus communication offer precise control over machining tools, enhancing accuracy in the production of parts.

- Building Automation: Modbus enables stepper motors in HVAC systems, blinds, and security systems to be monitored and adjusted remotely, improving overall building efficiency.

Challenges and Considerations

While Modbus offers many benefits, there are also some challenges when implementing this protocol with stepper motor drivers:

- Network Reliability: Modbus communication relies on network stability. Any interruptions or delays can affect the performance of the system.

- Data Latency: Real-time systems require minimal delays in communication. Engineers must optimize the Modbus network for speed to avoid latency issues, especially when multiple devices are connected.

- Complexity: Setting up a Modbus network and configuring devices may require additional expertise, particularly in large or intricate systems.

Despite these challenges, the advantages of using Modbus for stepper motor control far outweigh the potential drawbacks, particularly in industrial applications where communication and control play a vital role in system performance.

Integrating Modbus into stepper motor systems significantly enhances the capability to control and monitor motors remotely, making it a valuable tool for improving both efficiency and reliability. As we will see in the next chapter, modern advancements in USB stepper motor controllers are providing even more flexibility in controlling these motors, especially in smaller or portable systems.

The Role of USB Stepper Motor Controllers in Modern Systems

As technology continues to evolve, the need for compact, easy-to-use solutions for controlling stepper motors has led to the rise of USB stepper motor controllers. These devices offer a versatile and user-friendly way to integrate stepper motor control into computer-based systems, making them particularly valuable for applications in research, development, and hobbyist projects. Unlike traditional stepper motor drivers that may require complex wiring or specialized equipment, USB stepper motor controllers connect directly to a computer via a USB port, simplifying control and setup.

What is a USB Stepper Motor Controller?

A USB stepper motor controller is a device that allows a computer to communicate with and control stepper motors through a USB interface. It typically includes a microcontroller that interprets signals from the computer, such as motion commands and parameters, and converts them into appropriate control signals for the stepper motor driver. USB stepper motor controllers are designed to be plug-and-play, meaning they can be easily connected to a computer without the need for additional hardware or complicated setup procedures.

Once connected, users can use specialized software to control motor speed, direction, steps, and more. Many USB controllers also provide feedback on the motor’s status, such as position and current consumption, ensuring that the motor operates within safe parameters. These controllers are widely used in applications ranging from 3D printing and CNC machining to robotics and experimental setups.

Benefits of USB Stepper Motor Controllers

Ease of Use: The primary advantage of USB stepper motor controllers is their ease of integration. Connecting a motor to a USB controller eliminates the need for a complex wiring setup, making it much simpler for users to control motors directly from a computer.

Portability: USB controllers are typically compact, portable devices, making them ideal for mobile or field applications where space is limited.

Software Compatibility: These controllers are often accompanied by software that allows for intuitive, graphical control of the stepper motors. This can range from basic applications to complex custom-designed software tailored to specific needs.

Real-Time Control: USB stepper motor controllers offer real-time control, allowing users to adjust motor parameters, such as speed or position, in response to feedback from sensors or external systems.

Cost-Effective: USB stepper motor controllers are generally more affordable than larger, industrial-grade controllers. This makes them particularly attractive for prototyping and educational purposes.

Common Applications of USB Stepper Motor Controllers

USB stepper motor controllers have found a wide range of applications, particularly in fields that require precise motor control without the complexity of traditional setups:

- 3D Printing: USB controllers are commonly used to manage stepper motors in 3D printers, controlling the movement of the print head and the build platform with high precision.

- CNC Machines: In CNC (Computer Numerical Control) systems, USB stepper motor controllers allow for the precise movement of cutting tools, helping produce detailed and accurate parts.

- Robotics: USB stepper motor controllers enable easy control of stepper motors in robotic arms and other robotic systems, where precise movement is crucial for tasks like assembly, packaging, or testing.

- Prototyping and Research: Engineers and researchers use USB controllers for testing and experimenting with stepper motors in various applications, taking advantage of their simple setup and real-time control capabilities.

Limitations of USB Stepper Motor Controllers

While USB stepper motor controllers offer many benefits, there are a few limitations to consider:

Limited Power Handling: USB controllers are generally designed for low to medium power applications. For high-power motors or industrial-grade systems, a more robust driver may be necessary.

Limited Number of Motors: Most USB controllers are designed to control a single motor at a time or a small number of motors, which can be a limitation for large-scale systems requiring multi-axis control.

Dependence on a Host Computer: USB stepper motor controllers require a connection to a computer for operation. This makes them less suitable for standalone applications or systems where a computer may not be readily available.

Advanced Features in USB Stepper Motor Controllers

Many modern USB stepper motor controllers come with advanced features that enhance their functionality:

Microstepping: Some USB controllers support microstepping, which allows for smoother movement and greater positional accuracy by dividing each step into smaller sub-steps. This is useful in applications where precision is critical.

Multiple Motor Control: Some advanced USB controllers can control multiple stepper motors simultaneously, making them suitable for multi-axis machines like CNC routers or robotic arms.

Real-Time Feedback: Many USB controllers are equipped with real-time feedback mechanisms, allowing users to monitor motor performance, such as current consumption, speed, and position, directly from the software interface.

USB stepper motor controllers represent a breakthrough in simplicity and accessibility for motor control. By offering a direct interface between a computer and stepper motors, they simplify setup, reduce costs, and enable greater flexibility in controlling and monitoring motor systems. While they may not be suitable for every application, particularly high-power or industrial systems, they are an invaluable tool for a wide range of fields, from hobbyist projects to professional prototypes. The advent of USB controllers has significantly democratized access to precise motor control, making it easier than ever to harness the power of stepper motors for both simple and complex applications.

In the next chapter, we will tie together the previous discussions, highlighting how advancements in stepper motor drivers, current management, Modbus integration, and USB controllers contribute to a more efficient and precise stepper motor-driven system.

Integrating Stepper Motor Drivers for Precision and Efficiency

Stepper motors are a cornerstone of precision motion control, widely used in industries ranging from manufacturing and robotics to medical devices and consumer electronics. To unlock the full potential of these motors, a deep understanding of stepper motor drivers and their key components is essential. In this article, we’ve explored the importance of stepper motor drivers, current management, Modbus integration, and USB controllers, each contributing to the motor’s performance and versatility in different ways.

The stepper motor driver remains the most critical component in ensuring reliable, precise motion. By controlling the electrical pulses sent to the motor, the driver regulates speed, direction, and torque, making it a crucial part of any stepper motor-based system. Moreover, proper current management is vital for maintaining efficiency and preventing damage. Effective current control prevents overheating and ensures the motor operates within safe limits, maximizing both performance and longevity.

Integrating Modbus communication further enhances the functionality of stepper motor systems. By enabling remote control and real-time feedback, Modbus allows stepper motors to be seamlessly incorporated into larger, more complex systems. This integration is especially beneficial in industrial automation, where precise coordination and scalability are required. Stepper motors with Modbus support enable centralized control, improved diagnostics, and enhanced monitoring, making them indispensable in many applications.

On the other hand, USB stepper motor controllers offer an accessible and user-friendly solution for controlling motors in smaller-scale or experimental settings. The ease of integration with computer systems, along with the flexibility and portability of USB controllers, has opened up new possibilities for hobbyists, engineers, and researchers alike. Though typically designed for lower-power applications, USB controllers are a powerful tool for precise motion control in areas such as 3D printing, CNC machining, and robotics.

In conclusion, the combination of advanced stepper motor drivers, current regulation techniques, Modbus communication, and USB control interfaces creates a robust system for achieving precision and efficiency in stepper motor-based applications. Understanding and implementing these technologies allows engineers and designers to fully harness the capabilities of stepper motors, ensuring they operate at peak performance and deliver reliable results in a wide range of environments. As these technologies continue to evolve, the potential for even greater control, flexibility, and innovation in motion systems will only increase.